How Does a Speed Controller Work: Exploring the Mechanisms and Applications

Driving a car, we often take for granted how the simple press of a pedal controls the vehicle’s speed. Akin to an accelerator pedal, a speed controller is the unsung hero of the electronics world, an ingenious device that manages the speed of an electric motor by regulating the voltage or current flow. Picture this: the electric motor is like an engine, hungry for energy and the speed controller – it’s the chef, serving just the right amount to keep things running smooth and steady. Critically important in a myriad of applications, these devices help drones soar and electric cars move, all while exercising energy efficiency. Stick around as we dive deeper into the fascinating world of speed controllers – I bet by the end of it, you’ll see them in an entirely new light, and just maybe, appreciate the next fan or remote-controlled toy you use a little bit more.

Explaining Speed Controller Technology

Just imagine an artist creating a pointillist artwork. Each dot of paint varies in density, shaping a masterpiece- that’s quite similar to how a Pulse Width Modulation (PWM) Speed Controller functions. This little technological marvel adjusts the ‘density’ of electrical voltage applied, mirroring the artist’s finesse, to control the motor’s speed. Want to delve deeper into the world of PWM controllers? Do pay a visit to the comprehensive guides on Newbie Electronics.

On the other hand, a Phase Locked Loop (PLL) Speed Controller works differently. Imagine a pair of skilled dancers gracefully maintaining their rhythm with each other. Simply magical, isn’t it? That’s precisely how a PLL controller creates a ‘dance’ between the input frequency and the output frequency, ensuring they move in synchronisation. Yes, technology can be quite poetic! Websites like RobotShop can give you a more detailed insights into PLL controllers.

And that’s what fascinating about how a speed controller works! From artists to dancers, we’ve got neat analogies to assist your understanding of these fascinating devices. Whether it’s a PWM or a PLL, each type of speed controller has a unique mechanism that makes electric motors dance to its tunes.

What is a Phase Locked Loop (PLL) Speed Controller and how does it work?

Sure thing! A Phase Locked Loop (PLL) Speed Controller is your friend if you’re looking for stable, precise motor control. With this tech-savvy pal, you’ll never lose sleep over erratic and uncertain speed adjustments. The magic lies in how it’s structured – it contains components like a voltage-controlled oscillator and a phase detector, all happily working together in a feedback system. Now, let’s decode how it does all this, shall we?

When the speed of your motor changes, the PLL feels it – it’s quite the empathetic gizmo! Its phase detector senses the shift in speed and produces an error signal reflective of the difference between the input signal and the VCO frequency. What’s that, you ask? VCO stands for ‘Voltage-Controlled Oscillator’, the crafty little thing that generates an output frequency, which is directly proportional to its input voltage.

Well, the error signal from the phase detector, like a concerned confidant, steps in and corrects the VCO. So, if your motor speed faltered, the PLL would ensure that it gets right back on track. The result? Your motor maintains its desired speed. Isn’t that just bootstrapping brilliance? A daring dance of detection, correction, and stability – that’s what a PLL Speed Controller brings to the party! And we get to reap its benefits, making our lives a tad bit easier and our machines a tad bit smarter.

Simplifying the Complex: How a Speed Controller Makes All the Difference

So, how does a speed controller work? A speed controller essentially performs two crucial tasks: it controls the frequency of the power supply distributed to the motor, and it regulates the quantity of current being delivered. Think of this as a managed flow, the old adage, “it’s not a sprint, but a marathon” beautifully illustrates this. Just as a runner paces themselves to endure the length of a marathon, the speed controller smartly manages the electrical flow to extend the motor’s lifespan.

This concept might sound complex, but make no mistake, it is beautifully simple and essential. Let’s break it down. The speed controller expertly controls the power frequency delivered to the motor. In simple terms, it plays the role of a metronome, setting the pace — too fast, and you risk overworking the motor; too slow, and you lack efficiency. Websites like Schneider Electric provide interesting insights into the technology behind this mechanism.

Next, the speed controller manages the amount of current to the motor. This could be likened to a water tap; turn it too high and there is a deluge, too low and it’s just a trickle. It needs to find the ‘Goldilocks’ level, just the right amount of current for optimum motor performance. Both these processes work together seamlessly, ensuring your device works at its best.

From big industries to your home appliances, understanding how a speed controller works lets us appreciate the micro-controls that happen behind the scenes. From drones hovering in the sky to electric cars plying our roads, these all depend on how well the speed controller does its job. So the next time you enjoy a smooth ride or marvel at a drone’s flight, you’ll know a little more about how it’s all made possible.

What industries or devices rely on speed controllers for optimal performance?

You’d be amazed at how crucial speed controllers are in so many of the gadgets and industries we interact with daily! Look at robotics, for example – those precise, deliberate movements? All thanks to adept speed control.

Transportation industry is another biggie. Ever flown in a drone or cruised in an electric car? Speed control tech is what makes these rides smooth and enjoyable. Don’t even get me started on elevators and escalators. The ‘up and down’ in a controlled fashion, my friend, is courtesy of speed controllers.

We see speed controllers playing their part in the HVAC industry as well, controlling blowers and pumps for optimal comfort. And who can ignore their role in the manufacturing industry where conveyor belt speeds are critical for optimum productivity and safety?

Even home appliances, like your handy blender or your trustworthy washing machine, rely on these unsung heroes to function smoothly.

So next time you use one of these devices or interact with these industries, give a silent nod to the silent work of speed controllers at play. Quite the unsung heroes, aren’t they?

Speed controller basics

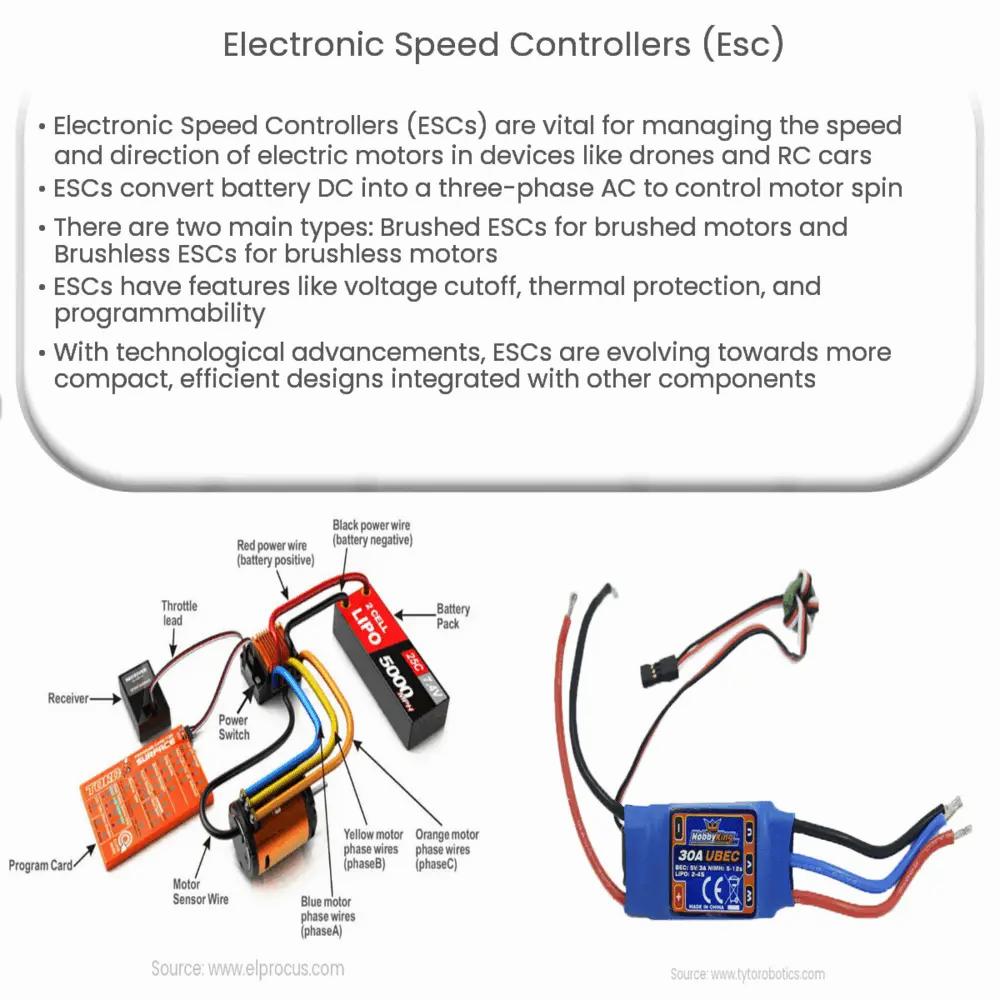

Speed controllers have become indispensable in our lives with their application spanning across a multitude of industries. Let’s zoom into the drone industry – a burgeoning market that is expected to surpass US$22 billion by 2022, according to Statista. You might ask, “how does a speed controller work in a drone?” The answer lies in the precision of the controller’s operation which regulates the rotational speed of drone propellers resulting in smooth and controlled flight.

Taking the example of quadcopter drones, the controller regulates the speed of each propeller individually to maintain stability and responsive control. Too slow and the drone can’t lift-off; too fast and the drone might lose control. This is where the art of balancing comes in, and our silent performer, the speed controller, does its job efficiently and methodically.

On the other hand, let’s not forget about their use in more domestic applications. Electric fans, for instance. The remote control you use to adjust the fan speed is a classic example of a speed controller at work.

From drones to fans, from cars to boats, speed controllers have proven to be revolutionary in assisting us to control the very essence of motion – speed. Truly, without speed controllers, our progression towards increasingly sophisticated technology would have hit a speed bump!

Clearly, understanding how a speed controller works brings new appreciation to these silently operating, yet crucially significant devices in our lives.

What industries use speed controllers besides drones and electric fans?

That’s an interesting question! While drones and electric fans might spring to mind when thinking about speed controllers, there’s actually a solid list of industries that use them quite a bit. For instance, the automotive industry greatly depends on these handy devices. If you’ve ever kicked your car into cruise control or marvel at hybrid vehicles consuming less fuel, you’re seeing speed controllers at work. Likewise, in the manufacturing sector, speed controllers are invaluable for controlling conveyor belts, assembly lines or even robotic arms. Think about the careful speed needed to assemble microchips!

Additionally, marine vessels and railways use them to regulate the speed of engines, offering smoother rides and better fuel efficiency. Even entertainment industries use them – from controlling the speed of roller coasters to managing special effects on movie sets. And we’re not done yet – in the renewable energy sector, speed controllers are used in wind turbines to maximize energy production. Picture this: if the wind is too strong, the turbine automatically adjusts its speed to prevent damage. Super cool, right?

Honestly, it’s almost like asking, where don’t we see speed controllers! They truly are the unsung heroes, silently ensuring efficiency, safety, and precision across a myriad of industries. Isn’t it fascinating how those little devices you know from drones have such a far-reaching impact?

How Speed Controllers Work

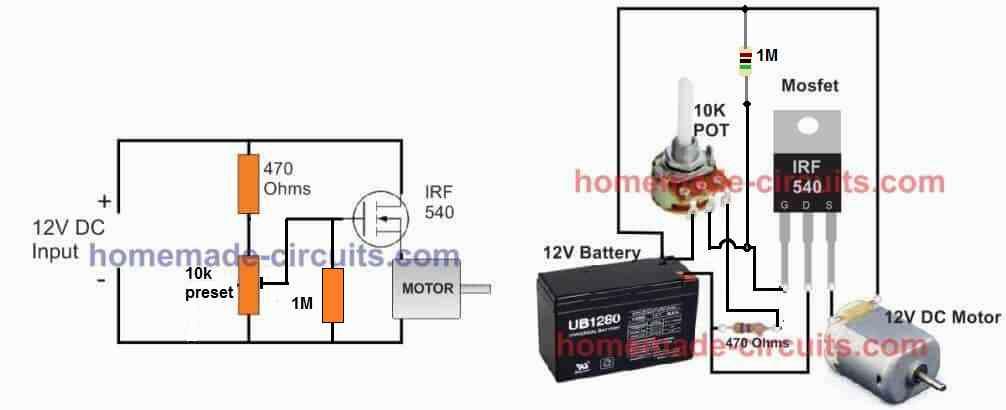

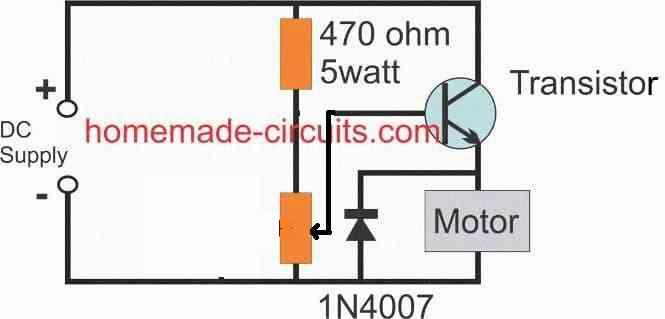

Choosing the right speed controller for your specific needs can feel a bit like finding a needle in a haystack. With the expansive range of options available, it’s critical to take several factors into consideration. These include the motor current, voltage, and type (whether it’s brushless or brushed).

- Motor Current: Think of the motor current as the strength of the electrical flow. It’s essential to choose a speed controller that can handle the current your motor needs. A mismatch could lead to overheating, and we definitely don’t want a fried circuit on our hands!

- Voltage: This one’s about, well, the potential power. Choosing a controller with determinable voltage tolerances in line with your motor’s requirements can help ensure its smooth operation. Go too high or too low, and the motor might just stage a protest!

- Type of Motor: Brushless or brushed? This isn’t just a decorative choice. The different structures of these two types mean they work differently, hence need different types of controllers. Be cautious about this aspect, or you might be setting yourself up for a physics fail!

The key question driving your selection should always be, ‘what is the job of my motor?’. Knowing whether its job is to power your cool quadcopter drone or a simple table fan will play a huge role in making the right choice. After all, you wouldn’t hire a chef to fix your plumbing, would you? Websites like HobbyKing offer a comprehensive guide on choosing the right speed controller to navigate this task. Understanding how does a speed controller work, and more importantly, what its role in your specific setup will be, becomes significantly easier with this knowledge. Happy choosing!

What factors should I consider when choosing a speed controller for my motor?

Choosing the perfect speed controller for your motor doesn’t have to be as tricky as it sounds. First things first, you need to factor in your motor’s voltage and current requirements. This is the lifeblood of your motor, folks! Make sure to pick a speed controller that can handle the maximum voltage and current of your motor – anything less might result in disappointment. While we’re at it, let’s also chat about compatibility. A motor and its controller should work together like peanut butter and jelly. Brushed or brushless – make sure they match!

Now, here’s a pro tip – keep the environment in mind. If your motor encounters intense heat or cold, moisture, or dust, ensure your controller has the fortitude to withstand the same conditions. Don’t let Mother Nature beat it, right? Lastly, never overlook the importance of features. Yes, budget matters, but your controller’s dynamics – reverse function, variable speed controls, or a failsafe mechanism – could make or break your project. This isn’t just a component – it’s a teammate. Choose wisely!

Remember, there’s no one-size-fits-all answer here. It’s all about what you and your motor need. It’s a personal journey, my friend. Do your homework, consider all your needs, and you should be just fine. Good luck!

Wrapping up, the workings of a speed controller can feel complex, but the essence of it is rather simple. It’s just about managing the power flow, much like how our heart regulates the flow of blood in our body. Be it the hobby drone you fly on sunny afternoons, or the electric fan that keeps you cool throughout the summer, speed controllers are the heartbeat that keeps these machines going, ensuring a smooth and efficient performance. They embody the very essence of ‘how does a speed controller work’ by enabling precise control over electronic devices, quite like how a maestro conducts an orchestra. As digital and electronic inventions continue to grow and evolve, the role of speed controllers will become even more critical. So, the next time you see a drone in the sky, just remember the unseen heartbeat, sending pulses of energy to make that flight possible. After all, without speed controllers, our tech-enabled world would probably miss a beat!