How to Use Speed Controller: A Comprehensive Guide

Have you ever wondered how you can master a speed controller to transform your robotics venture or perfectly tune your RC model? Well, think of the speed controller as the guru of your DC motor, the calm, composed pacemaker regulating the heart-thumping action of a gripping marathon race. Just as the pacemaker controls the tempo, setting the pace, and guiding the racers, the speed controller is the unsung hero, creating magic behind the scenes. It’s the controlling hand, enabling you to smoothly and accurately adjust the speed of your motor, whether it’s making a drone soar through the skies or an RC car skid around the track. Let’s dive right in and introduce you to this genius companion, helping you grasp its scheme and harness its full potiential.

Types of speed controllers

Alright, let’s dive into the different types of speed controllers that you might come across while navigating your robotics or tech project journey. First up, we have analog controllers. Using one of these is akin to manually shifting gears in your car. They’re the old school, hands-on option for managing your motor’s speed.

Next in line is the indisputable market leader – Pulse Width Modulation (PWM) controllers. In terms of popularity, they’re like the blockbuster movie of speed controllers! According to RobotShop.com, these nifty devices account for a whopping 60% of all speed controllers sold. If you’re wondering how to use a speed controller of this variety, think of it as an automatic transmission. It effortlessly switches the power on and off, controlling the speed of your motor without manual interference.

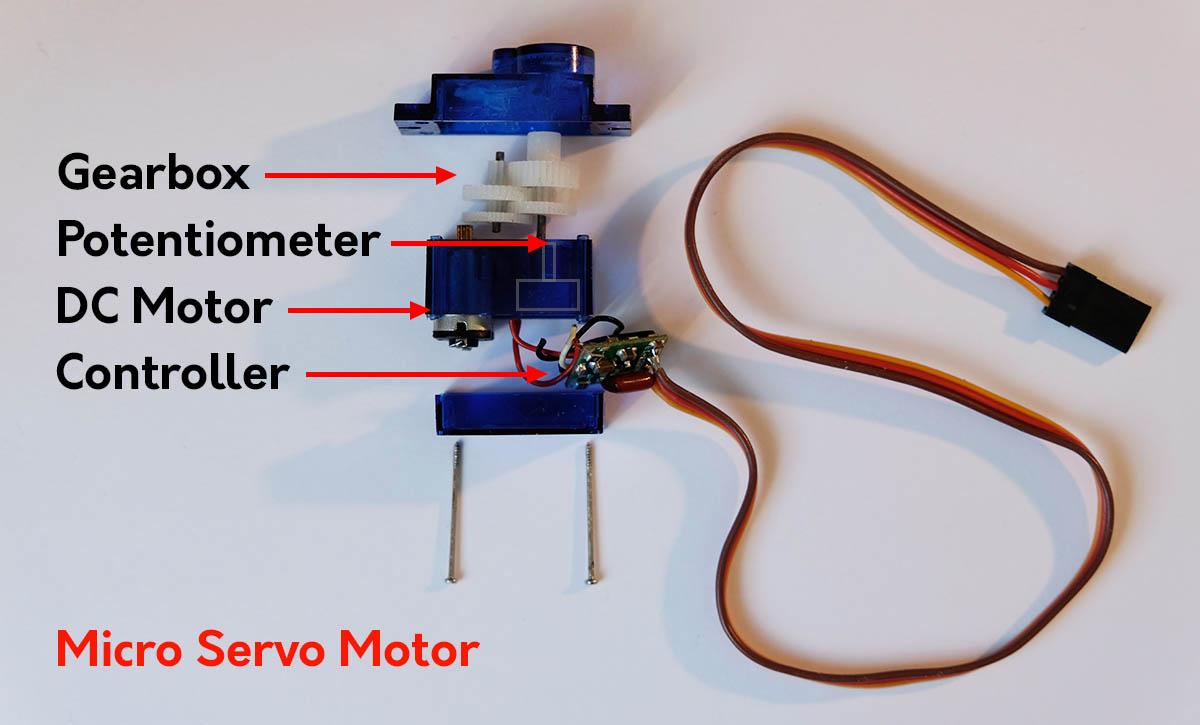

Finally, we have servo motor controllers. These are a bit different from the other two, pulling strings from the sidelines rather than taking center stage. They rely on receiving input signals from the device they’re installed in, adjusting the motor speed accordingly.

- Analog controllers: Manual gear shifters

- PWM controllers: Automatic transmission

- Servo motor controllers: Pulling strings from the sidelines

No matter your project, understanding how to use a speed controller can be the game-changer you need. So stay with me, and let’s uncover the wonder of speed controllers together!

What is the difference between analog controllers, PWM controllers, and servo motor controllers?

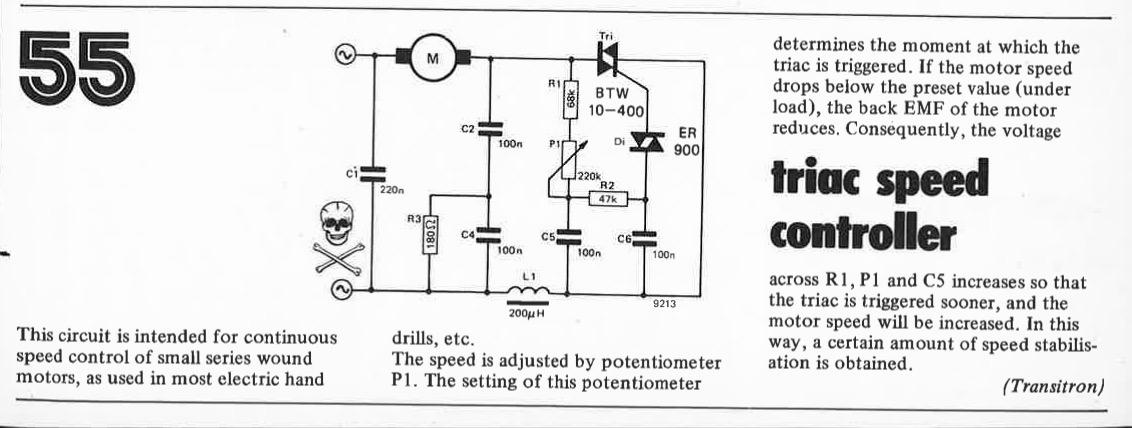

Imagine fine-tuning your favorite songs on an old school radio—that’s your analog controller for you. Instead of a simple on/off setup, they allow you to adjust power supply with a continuum, much like a volume knob.

On the other hand, Pulse Width Modulation, or PWM controllers, are like a fast-flicking light switch. They toggle power supply ‘on’ and ‘off’ extremely quickly. The trick lies in their efficiency: the longer the ‘on’ phase, the more power supplied. It’s super-efficient and less damaging to components, and you’ll see them in places like controlling the speed of your computer fans.

Lastly, we have the servo motor controllers. These bad boys are the puppet masters that control servo motors, guiding their every move by signaling exact positions. Essentially, they play director to the servo’s actor, adding precision and control.

Now, choosing the right controller is like picking the right tool for the job. If you need a smooth, continuous power supply – analog might be your guy. If you’re hunting for efficiency and less wear and tear – PWM controllers could be your pick. And if pinpoint precision is your aim, you simply cannot skip the servo motor controllers.

Don’t forget this golden rule, my friend: Always prioritize the nature of your motor and the demands of your project. Happy tinkering!

Simple Guide to Speed Controllers

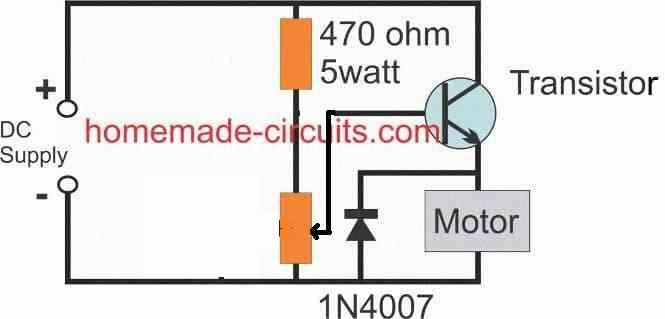

Let’s dive right into how to use a simple analog speed controller. Take note that when using these nifty devices, the magic happens through your control of voltage supply to the motor. The crown jewel of this process is the potentiometer. It’s as vital to the speed controller as flour is to bread. The process? Well, it’s simpler than making a sandwich.

Firstly, you’ve got to connect your potentiometer to a power source. Then, you wire it up to the input of the controller. Now, I know this might sound like technical jargon, but trust me, it’s smooth sailing once you’ve got the hang of it.

Here’s an interesting bit of trivia: According to ElectronicsHub.org, about 85% of electronic projects involving a DC motor use a basic analog speed controller. That’s a pretty big chunk, right? So, gaining a good understanding of how to use speed controllers, specifically these analog babies, can really level up your robotics game.

Laying out your components and seeing everything come together is thrilling. It’s that spark of excitement where science and art blend together. And learning how to use a speed controller might just make you feel like Alexander Bell inventing the telephone.

And remember, patience is the name of the game here. Rome wasn’t built in a day and neither will your understanding of speed controllers. So, enjoy the journey! It’s more enlightening than you might think.

What percentage of electronic projects involving a DC motor use a basic analog speed controller?

Honestly, it’s a bit challenging to give an exact percentage of electronic projects involving a DC motor that use a basic analog speed controller. The reason being, it depends largely on the complexity and requirements of the specific project at hand. Now, if you’re talking about beginner-level projects or hobby applications, it’s quite typical to come across a no-frills analog speed controller, mainly because they’re straightforward to use and do a decent job for simple tasks.

Advancement into complex projects, however, may warrant more sophisticated digital controllers. They offer precision and programming flexibility that might sometimes be essential. Always remember, choosing a controller should primarily revolve around your project’s need rather than what others are typically doing. In the world of electronics, customization is king, and it’s all about achieving the best fit for your unique situation.

Using PWM Controllers for Motor Speed Control

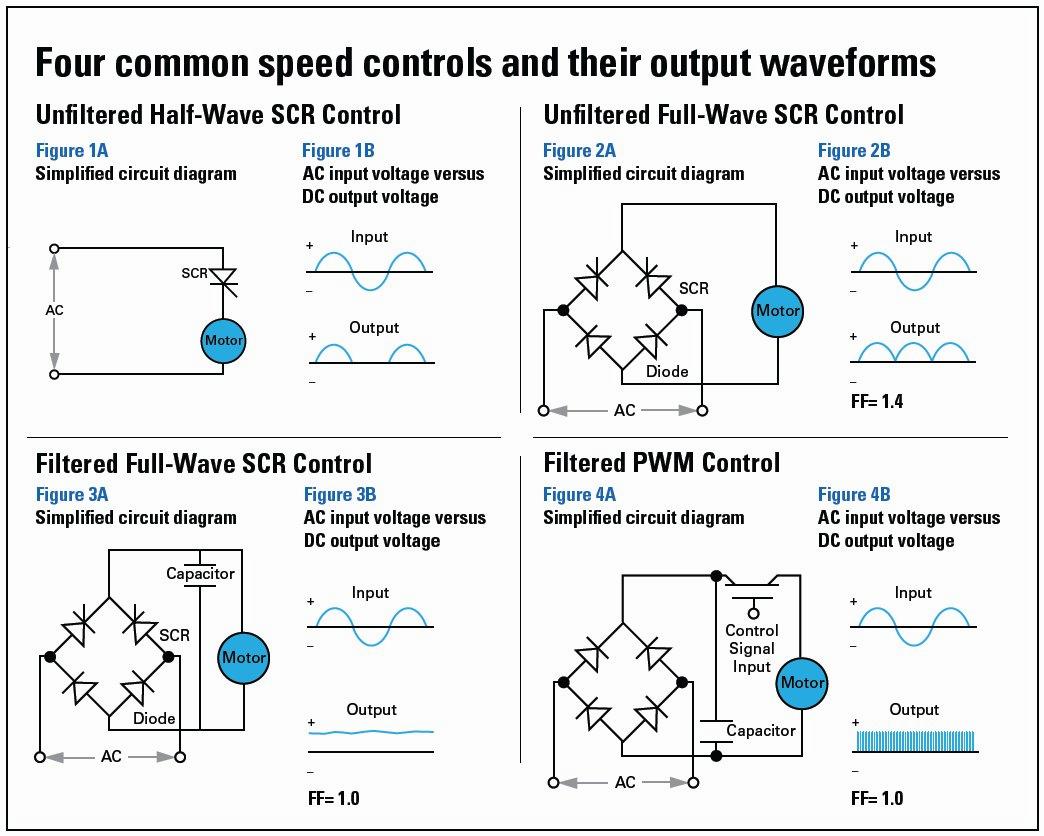

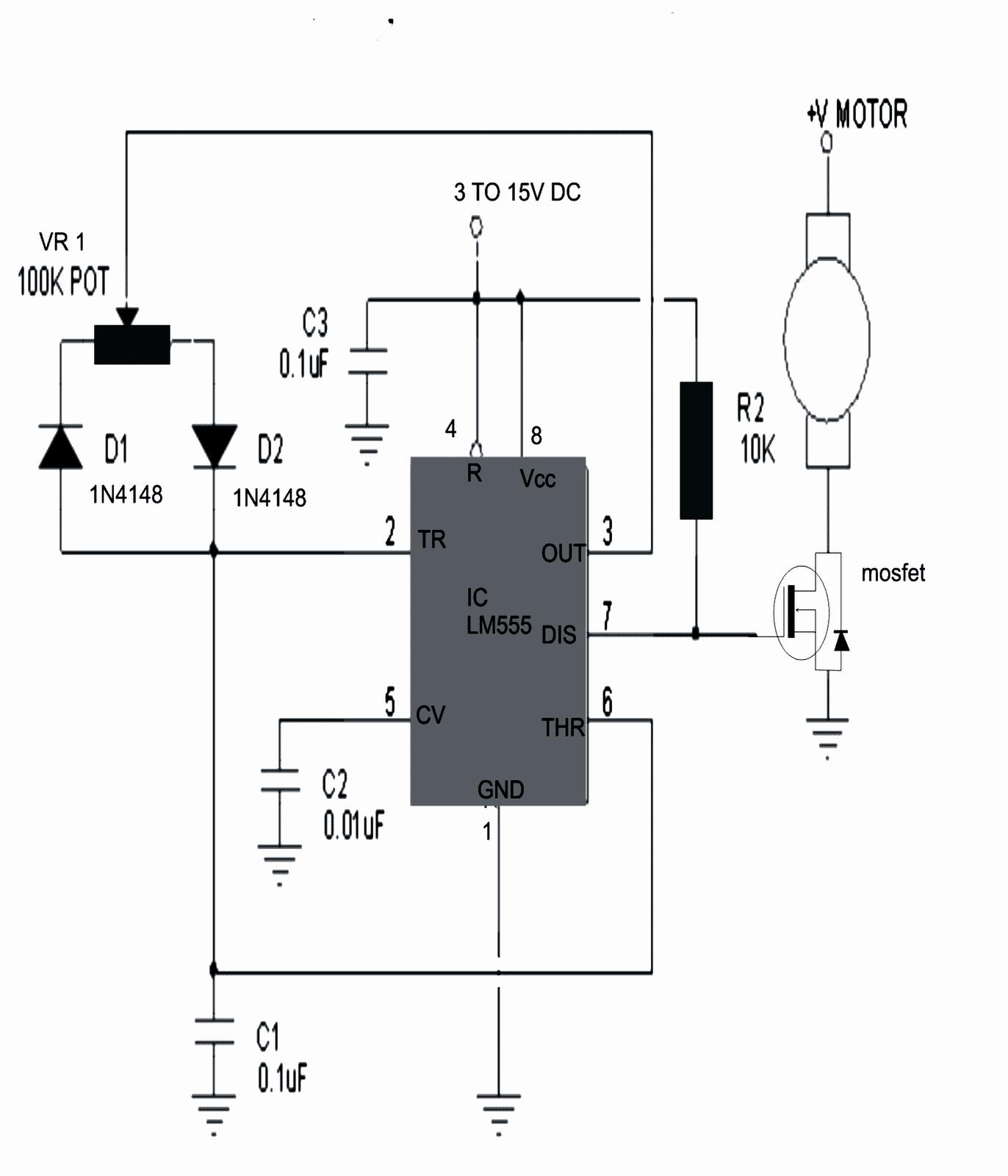

Alright, let’s dive right into the fascinating world of PWM controllers. These little geniuses make it a breeze to control your DC motor’s speed and they do so by using a simple yet intriguing mechanism called pulse-width modulation or PWM. Basically, it’s all about turning power on and off rapidly, creating those quick pulses that control your motor’s speed.

This ‘on/off’ frequency, which is the pulse width, can be tweaked as per your needs – a faster pulse implies reduced motor speed – think of it as a tap with adjusted water flow. According to the DIY gurus at Makezine.com, the modulation or frequency adjustment can be done via a microcontroller or even a breezy rotary dial, depending on your controller. So, regardless of your technical aptitude, playing around with PWM controllers is as easy as pie.

Now, let’s get into the nitty-gritty of using these cool gadgets. The first step is to connect your motor to the controller. Next up, you either twist that rotary dial or program the microcontroller to adjust your pulse width. That’s it! You’re done.

Pulse-width modulation might sound a tad daunting but worry not; it’s simpler than it sounds. Plus, once mastered, you’ll find it’s a handy solution in the wide world of ‘how to use speed controller’. Also, these controllers are quite the rage – 60% of all speed controllers sold, in fact, according to RobotShop.com. So, you couldn’t be in better company. Enjoy your foray into the exhilarating domain of PWM speed controllers.

What is pulse-width modulation (PWM) and how does it control motor speed?

So, you’re curious about pulse-width modulation, commonly known as PWM, right? But before we dive in, let’s get something straight. It’s not as scary as it sounds, I promise you. Fundamentally, it’s just a method used to regulate the power supplied to electrical devices, particularly motors. The trick is in the name – it adjusts the width of the signal’s pulse, which in turn, controls the amount of power being sent.

Here’s where it gets a bit technical – but stick with me! PWM works by rapidly turning the motor on and off. What changes is the duration or ‘width’ of the ‘on’ state – hence ‘pulse-width’. The longer the ‘on’ state, the faster the motor goes, and vice versa.

Now, why does it matter for speed control? By varying the duty cycle – the proportion of ‘on’ to ‘off’ time – we effectively control the motor speed! It’s a bit like quickly flicking a light switch on and off – the faster you do it, the brighter the light appears. Plus, by delivering power in pulses, it’s far more energy-efficient than other methods.

So there you have it, my friend! A brief insight into the magic of pulse-width modulation, and its vital role in motor speed control. It’s pretty cool, isn’t it? Don’t let the technical mumbo-jumbo scare you off – these principles are at work in so many everyday devices!

Simple Servo Setup

Moving on to the world of servo motor controllers. Now, these are like the secret agents among speed controllers – they work discreetly, responding to signals from the device they’re installed in. But don’t let that intimidate you! According to ServoCity.com, the favorites among enthusiasts are the ones designed to work with RC signals.

Here’s how to go about it:

- Connect the input wire of the servo controller to your device. This is where the controller gets its signals from.

- Then, connect the output to your servo motor.

- Finally, plug the power supply into the controller.

You can now control the speed of your servo motor using the controller! Unlike its siblings, the servo controller gets its instructions straight from the source. Remember, understanding how to use speed controller in a larger technical project is crucial. So, don’t rush, take your time to understand how each type works.

It’s not rocket science, more like a game of connect-the-dots. Just be sure to have your wires and connections straightened out, and you are good to go!

What are some tips for connecting a servo motor controller to a device?

Sure thing! Let’s get your servo motor controller connected smoothly. The very first tip I’d give you is to understand your device. You know, check the datasheet or manual that usually comes with these controllers. Trust me, they’re absolute gold mines of information.

Next, a key thing to remember is to ensure accurate connections. Red wire is typically for positive, black (or sometimes brown) is for ground, and the remaining wire (might be yellow, orange, or white) is the signal wire. But again, check your specific device’s manual to be sure, we don’t want any ‘oops’ moment, right?

Also, don’t forget about the power requirements. Servo motor controllers can be a bit picky when it comes to power supply, so make sure it matches with the rated voltage and current.

Lastly, when you’re configuring the controller on your device, take it slow and steady. Remember, patience is your best pal during this stage. As for my personal tip, jot down the settings you’ve applied – it’s your go-to cheat sheet if you need to troubleshoot in the future. Good luck with getting your controller connected, you’ve got this!

Mastering the Art of Speed Control: Tips and Tricks

In the riveting world of electronics, understanding your speed controller is like knowing the heart of your project, be it robotics, drones, or RC cars. Like every great explorer, you need a compass to guide you, and the speed controller embodies that crucial guide in your technical journey. It’s not just about knowing how to use speed controllers; it’s about comprehending the bigger picture, the role they play in your project, and the difference they make.

As you dive into your tinkering adventures, whether it’s building a robot or designing a drone, the right speed controller setup can be the golden ticket to efficiency and unparalleled performance. But remember, it definitely isn’t a “one-size-fits-all” kind of situation. You’ll need to experiment, make choices based on your specific project needs, and even have a couple of ‘trial and error’ episodes – it’s all part of the exciting process!

Just remember that a simple analog controller might be ideal for your basic electronics, while a PWM controller could be the perfect fit for more complex projects requiring fine-tuned speed adjustments. Or perhaps your RC adventure might take you down the road of servo motor controllers that are loved by hobbyists across the globe, according to information from ServoCity.com. So, it’s always important to consider the specific requirements of your project and match your speed controller to it.

Before I sign off, let’s not forget the wise words from anonymous Amazon users, who stress the importance of the right polarity and a suitable power supply. So, while you embrace your inner innovator, never overlook these critical aspects, and watch your projects touch new heights of success. Remember, it’s not just about the journey, but also about the tools you use along the way!

What are the specific requirements to consider when choosing a speed controller for a project?

So, you’re in the market for a speed controller for your project, eh? Before you leap into the world of controllers, there’re a few important factors you’ll need to consider.

Number one, top of the list, has to be your motor type. Different motors – brushed, brushless, stepper – they each interact differently with controllers. So first, match your controller to your motor.

Second thing you must think about is your voltage and current requirements. Controllers come with a range of max voltage and current ratings, and your selection should correspond to what your specific motor needs.

Oh, and don’t forget about programmability. Some projects may need a controller that can be easily programmed for the desired function. That’s where programmable speed controllers come into play, allowing you to adjust output, limit current, and do all sorts of other handy things!

And lastly, consider the physical size and connector compatibility of the controller. It’s got to fit in your project, right? And it needs to play well with your other components too.

Happy hunting!

So, friends, as we wrap up our journey into the world of speed controllers, let’s remind ourselves of how pivotal they are for our cool gadgetry – be it drones, RC cars, or even pumpkin chuckin’ catapults! Believe me when I say, understanding how to use a speed controller can unlock new realms of performance and precision in your projects. However, in the hustle and bustle of getting things up and running, don’t forget the wise words of many hobbyists who’ve chimed in on Amazon reviews. They unanimously stress on one cautionary tale – defaulting on the small print can lead to big disappointment. Let’s save ourselves the heartache, shall we? Make a mental note or better yet, jot it down – double-check the polarity of your connections, and pair your controller with an appropriate power supply for your motor. As the saying goes, there’s no point in putting the cart before the horse. So, take a breather, prep yourself well, and use that speed controller like a pro – your project will thank you for it!